Product Description

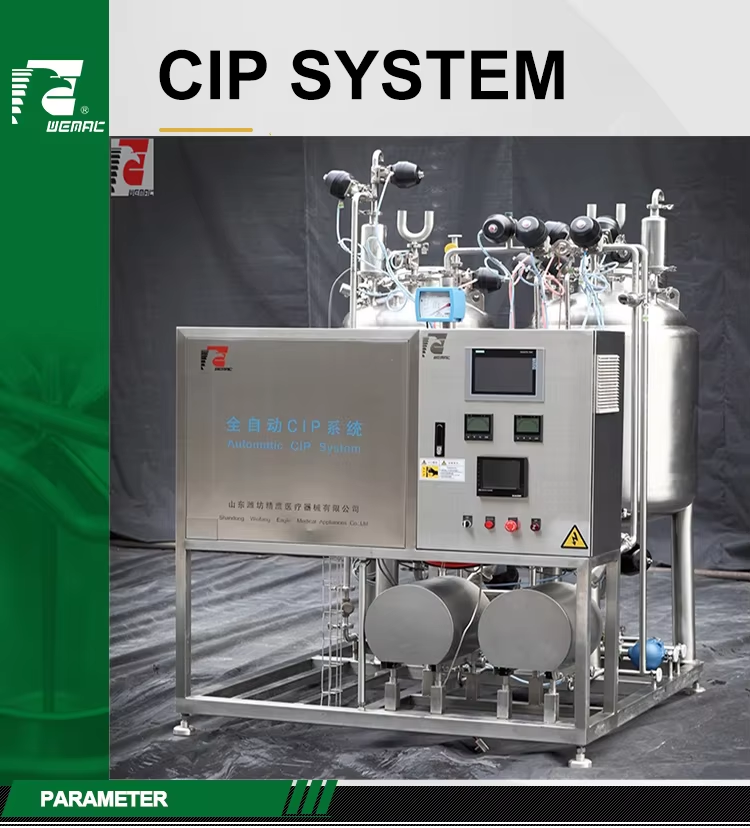

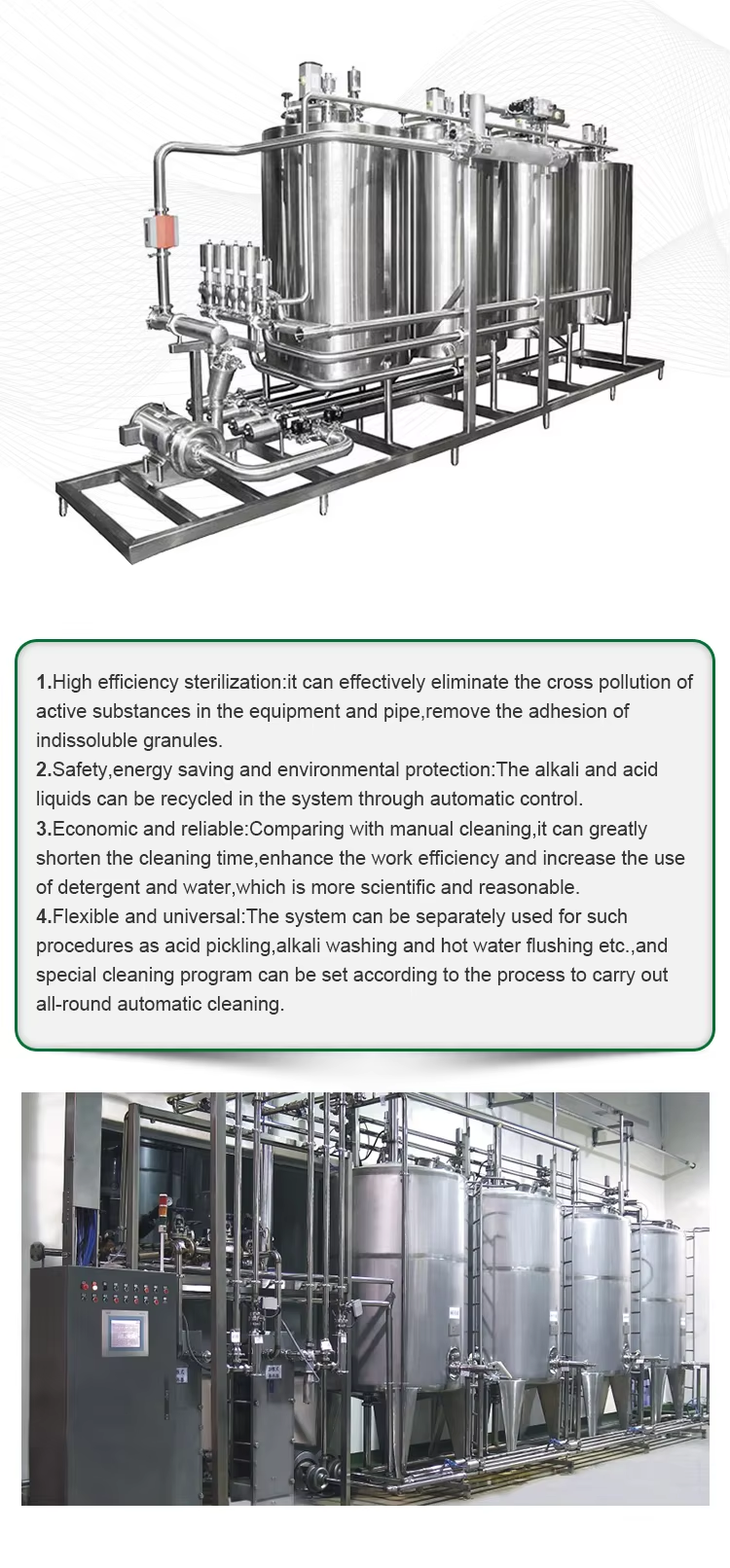

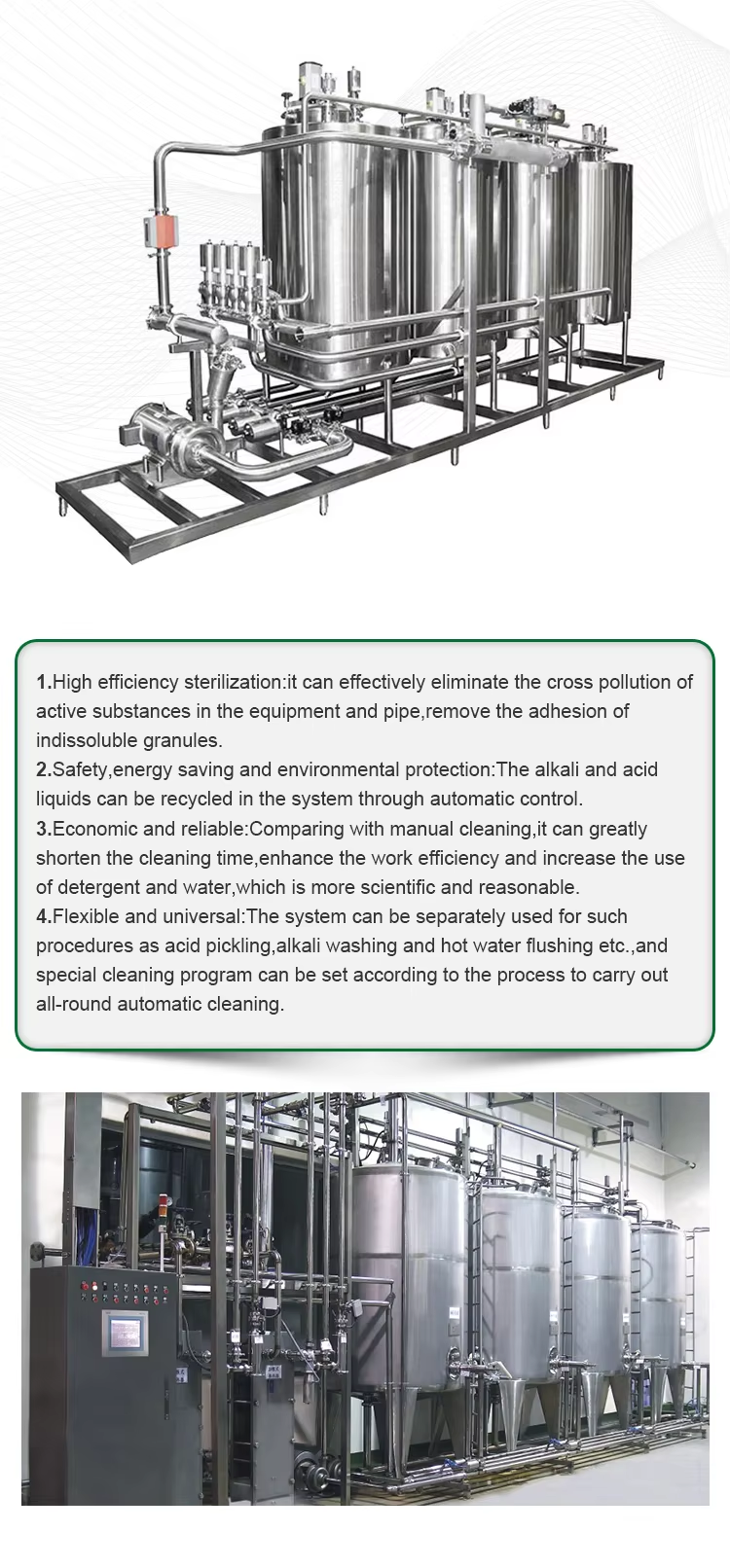

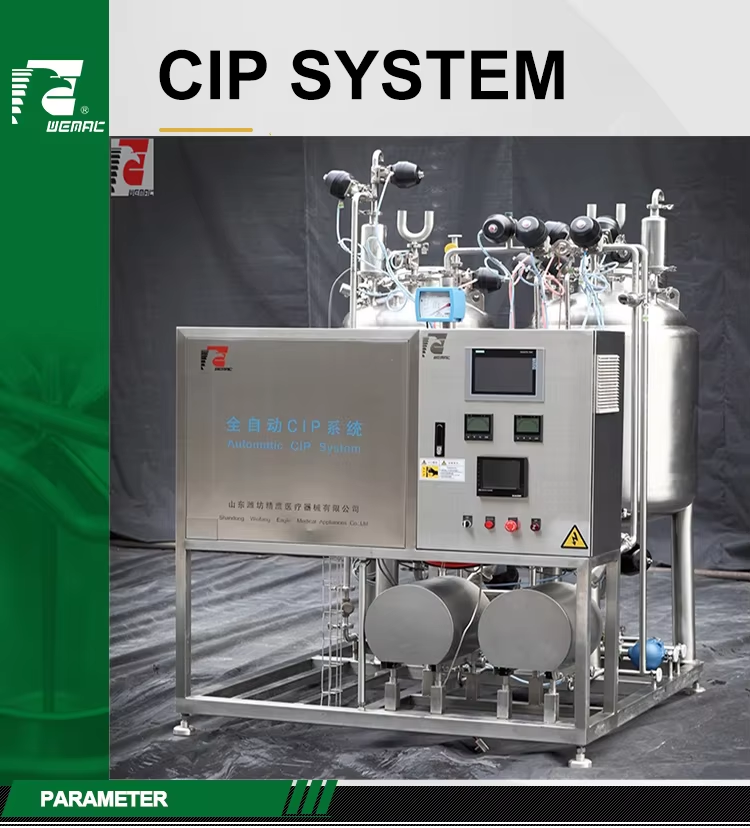

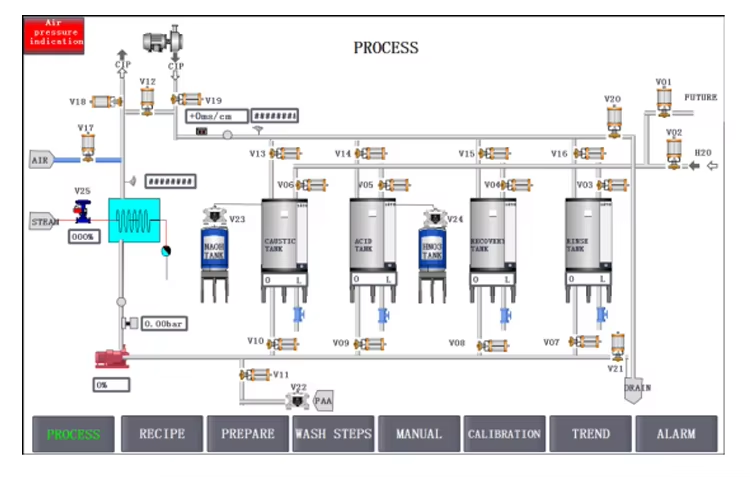

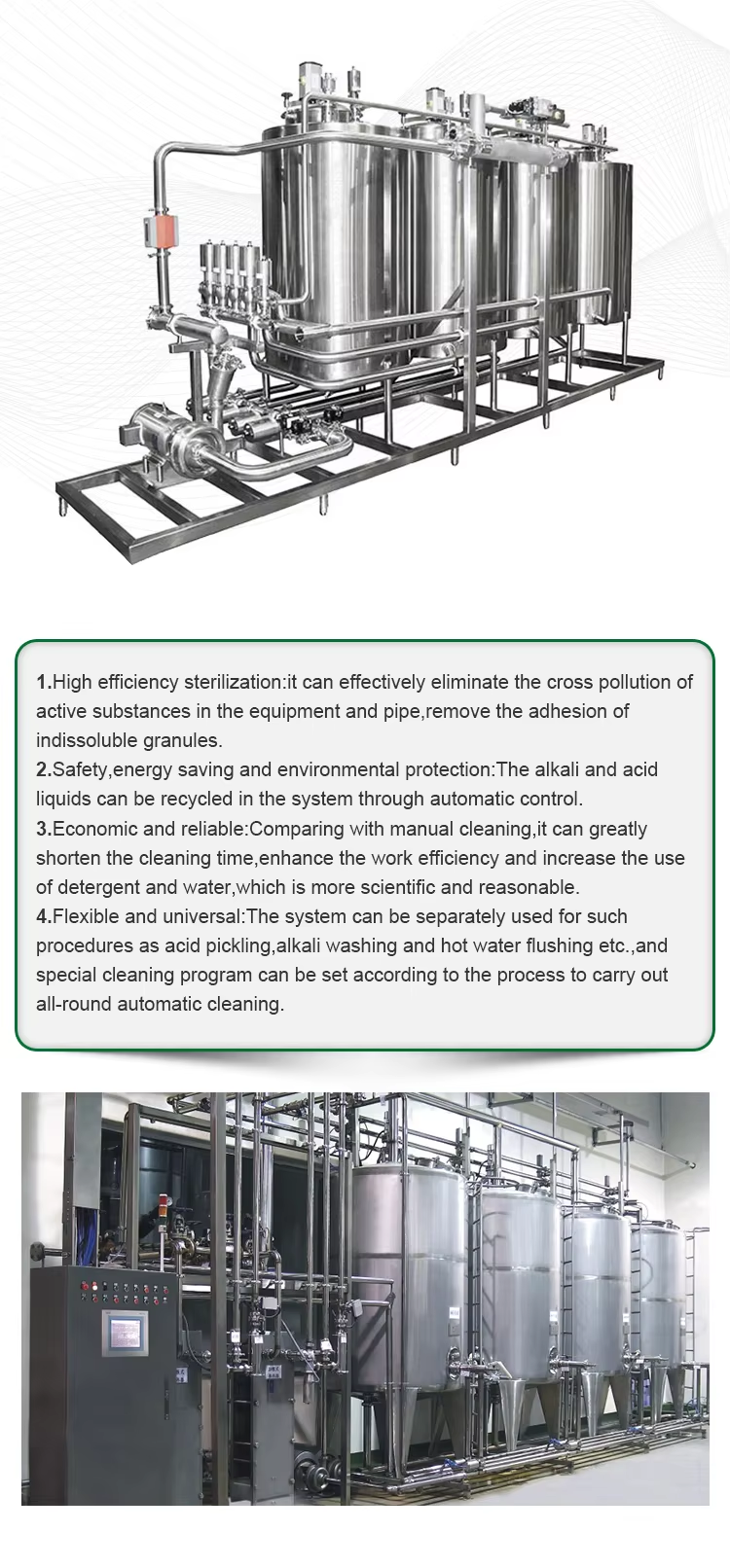

Introducing the ClP (Cleaning in Place) System by Eagle Pharma Machinery, a leading-edge solution designed to optimize the cleaning process of equipment and pipelines in the pharmaceutical, biotech, and healthcare sectors. This advanced system automates the cleaning process, ensuring that your equipment remains hygienic and compliant with industry standards. With a focus on innovation, reliability, and user-friendliness, this ClP system is a vital asset for any facility requiring top-tier cleanliness and operational efficiency.

Key Features:

-

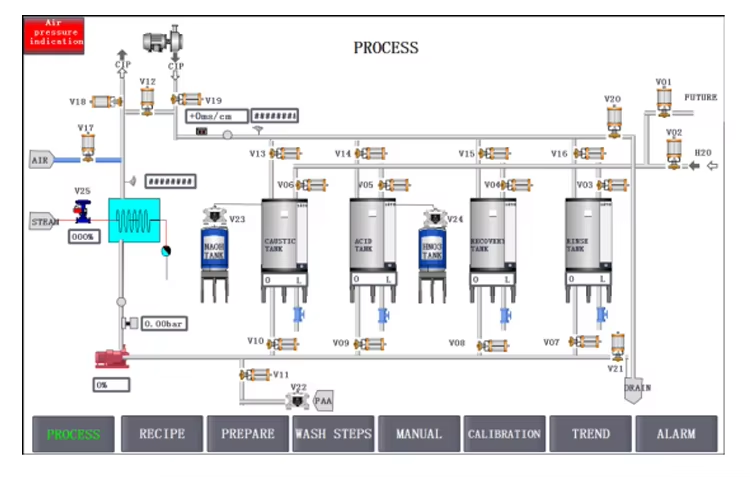

Automated and Consistent Cleaning: Ensures thorough and reliable cleaning cycles.

-

Customizable Programs: Designed to meet specific cleaning needs of equipment and pipelines.

-

Intuitive User Interface: Facilitates easy system management and operation.

-

GMP Compliance: Adheres to Good Manufacturing Practice guidelines for pharmaceutical manufacturing.

-

Durable and Robust Design: Ensures long-term reliability with minimal maintenance.

-

Comprehensive Support: Includes full documentation and validation support for regulatory compliance.

Applications:

- Pharmaceutical manufacturing equipment and pipelines.

- Biotechnological research and development facilities.

- Medical device production lines.

- Food and beverage processing equipment.

- Cosmetic manufacturing facilities.

- Any application requiring regular and efficient cleaning of equipment and pipelines.

Eagle Pharma Machinery's ClP (Cleaning in Place) System is more than just equipment; it's a promise of superior equipment hygiene and operational excellence. Rely on us to deliver the highest quality cleaning solution for your most critical applications.

Key attributes

Other attributes

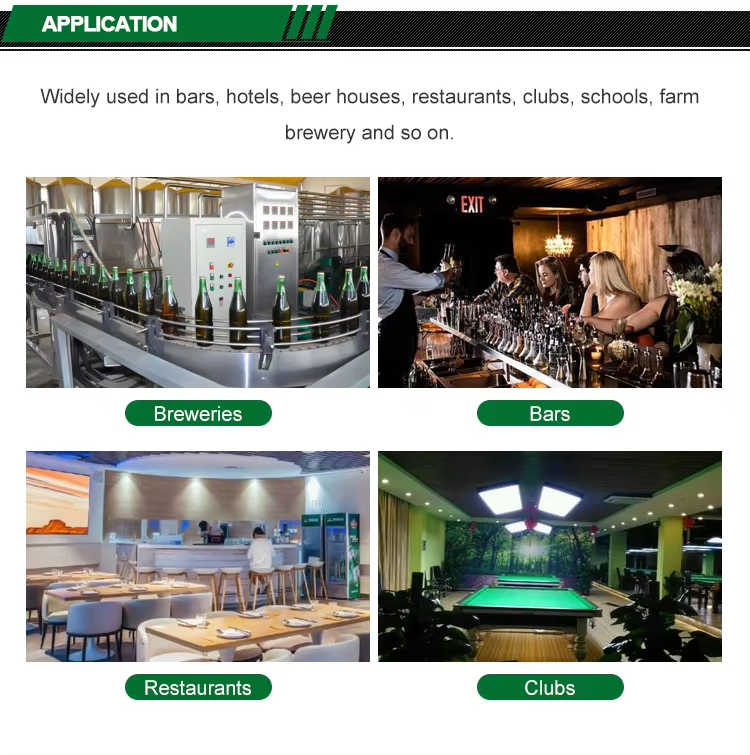

Applicable Industries

Hotels, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Food Shop

Showroom Location

Egypt, Spain, Thailand, South Korea, Colombia, Bangladesh, Uzbekistan

Video outgoing-inspection

Provided

Machinery Test Report

Provided

Marketing Type

Ordinary Product

Warranty of core components

1 Year

Place of Origin

Shandong, China

Dimension(L*W*H)

It depends on capacity

Processing Types

Beverage/diary/medical

Material

Stainless Steel 304 / 316L

Cleaning type

Liquid Cleaning

Packaging and delivery

Packaging Details

1. With export standard bubble film packaging, then for wooden case packaging for alone beer tanks and less brewery equipment.-LCL shipping.

2. If more tanks or complete set of brewery, with bubble film packaging, the for containers for FCL shipping.

3. By bulk carrier or independent containers, the size and quantity rely on the configurations and capacity.

4. Buyers requirement on packaging and shipping, tell us in advance.

5. Transportation method: By sea/Railway/Road/Air.

|

Material

|

SUS304

|

|

Capacity

|

According to requirement

|

|

Interior Shell

|

2B; TH=4mm

|

|

Exterior Shell:brushed plate

|

TH=2mm

|

|

Voltage

|

380V/220V

|

|

Power

|

1.5-2.2KW

|

|

Weight

|

5 Tons

|

◆100% TIG welding with pure argon gas shield;

◆The pipe mouth stretch technology and automatic tank welding equipment ensure the tank with no dead angle,no material residue and

easy to clean;

◆Tank polishing precision ≤0.4um,no distortion, no scratches;

◆Tanks and cooling devices are tested for water pressure;

◆3D technology application make customers know tank from different angles

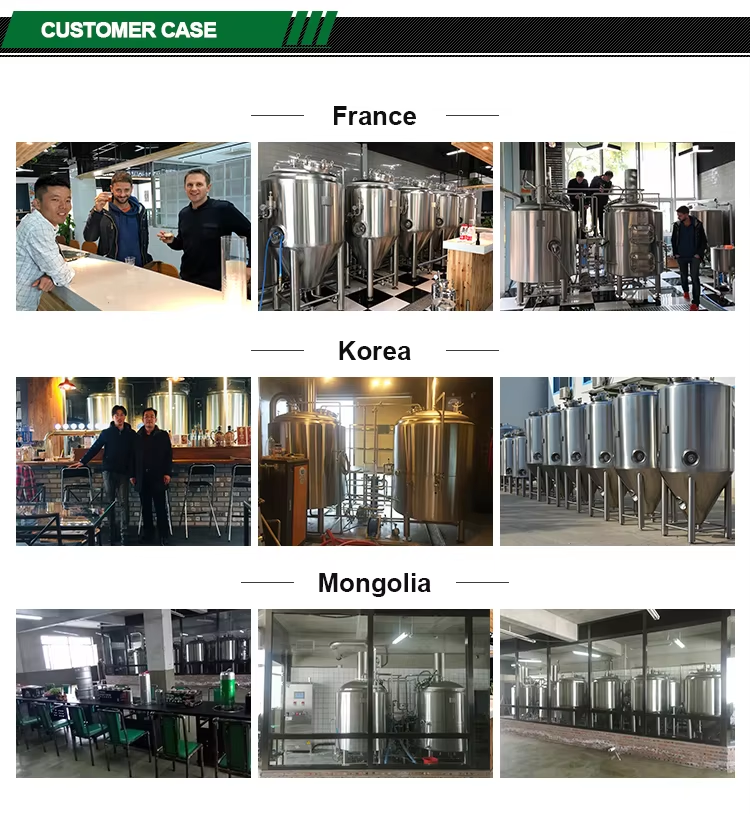

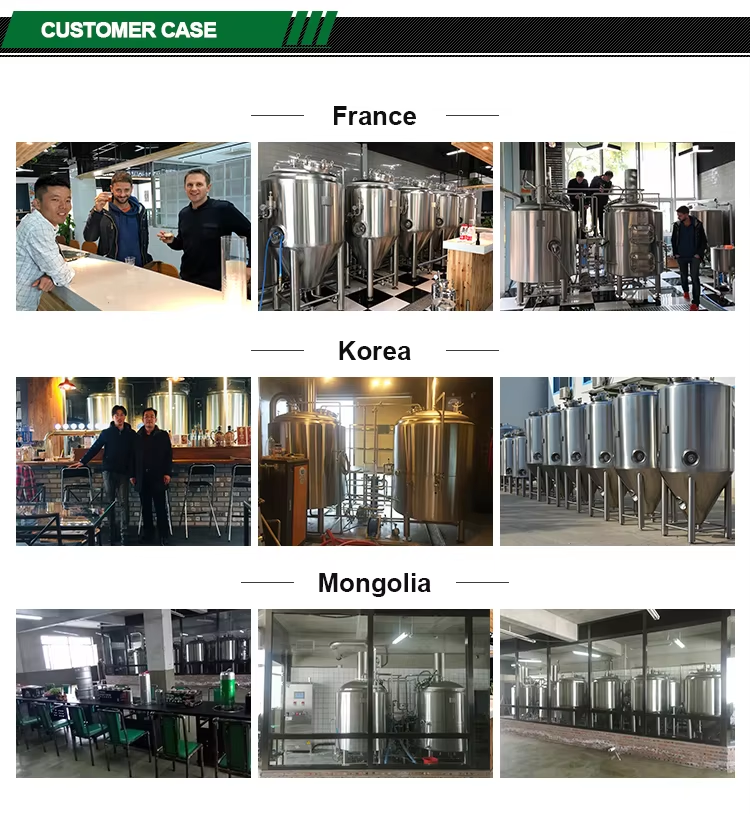

1. who are we?

We are based in Shandong, China, start from 2012,sell to Domestic Market(43.00%),North America(11.00%),South

America(9.00%),Western Europe(8.00%),Eastern Asia(5.00%),Southeast Asia(5.00%),Oceania(4.00%),Northern

Europe(3.00%),Africa(3.00%),Mid East(3.00%),South Asia(2.00%),Southern Europe(2.00%),Eastern Europe(2.00%). There are total about 201-300 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Purified water system/ Purified Water Generation Plant/ Multi Effect Water Distiller/ Multi Column Distillation Plant/ Pure Steam Generator/ Looping System/ Liquid Solution Preparation System/ Purified water storage tank/ Shell and tube heat exchanger/ WFI storage tank/CIP system/ Commercial Beer Brewing Equipment/ Fermentation System/ Home Brewing Equipment/ Microbrewery Equipment/ Nano Brewery Equipment/ Beer Filling Capping System/ Brewing Material Processing Machine/ Beer brewing Accessories,Ice Water Tank/

4. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,FCA;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken:English,Chinese,Korean