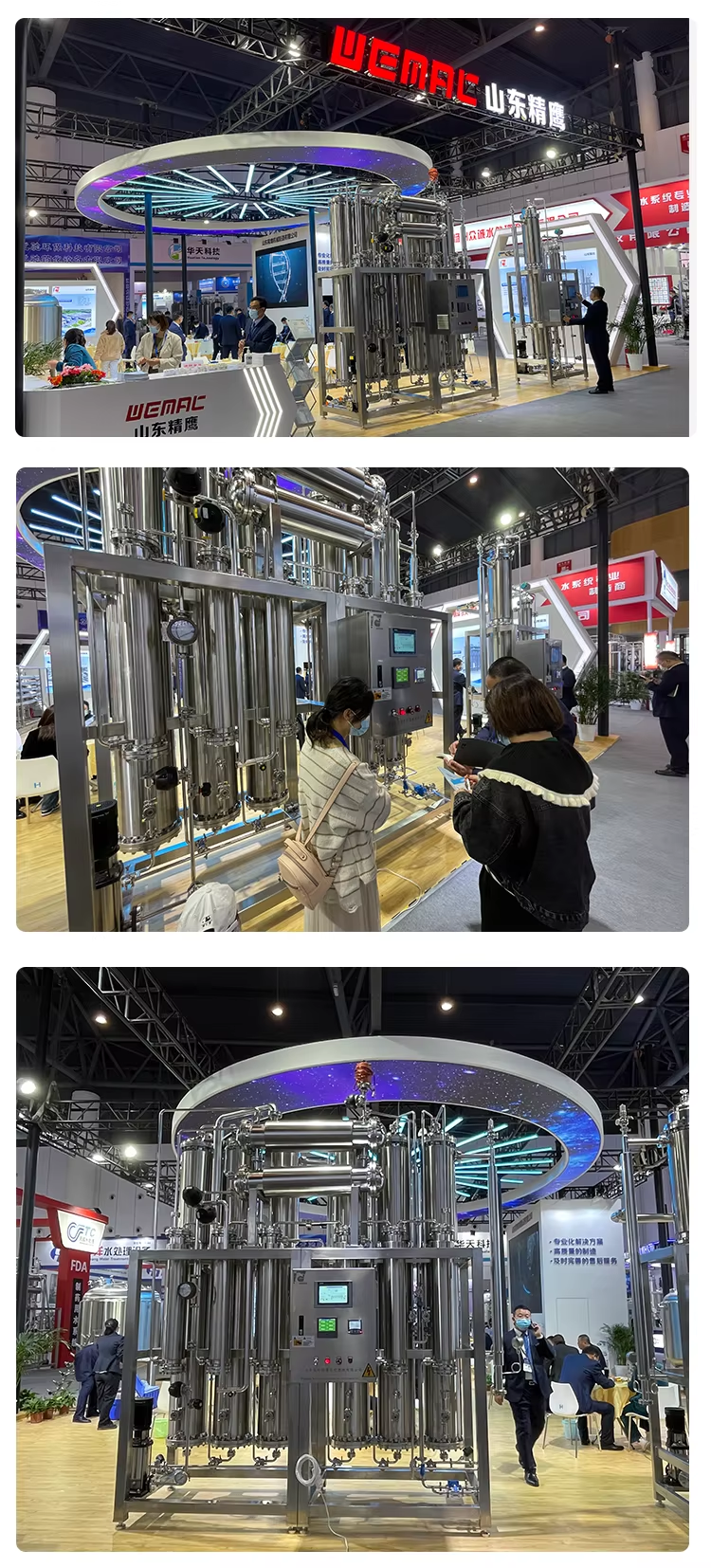

Eagle Pharma Machinery's Multi Effect Water Distiller & WFI Storage is a cutting-edge solution designed to meet the stringent water purity requirements of the pharmaceutical, biotech, and healthcare industries. This advanced system utilizes multiple effects to efficiently purify water, ensuring that your operations benefit from the highest quality water supply. With a focus on efficiency, reliability, and ease of use, this system is a cornerstone for any facility that demands uncompromised water quality.

Key Features:

Applications:

Eagle Pharma Machinery's Multi Effect Water Distiller & WFI Storage is not just a product; it's a commitment to excellence in water purity and operational efficiency. Trust us to provide you with the highest quality water for your critical applications.

WEMAC LDS series Multi effect water distiller is a kind of water for injection generation equipment using purified water as raw water, and heated by industrial steam. The water for injection produced by LDS series Multi effect water distiller meets the requirements of WFI in Chinese Pharmacopoeia (CP2020), United States Pharmacopoeia (USP43) and European Pharmacopoeia (EP10). Qualified raw water is pressurized by a multi-stage pump and then enters the condenser, and then enters each effect preheater in turn (the raw water is heated by secondary steam and distilled water in the condenser, and after entering each effect preheater is heated by condensed water of secondary steam, which will be heated by industrial steam condensed water in the first-effect preheater). Then it enters the first-effect evaporator and sprayed on the inner wall of the heating tube through the material water distributor, so that the material water flows in a film status on the tube wall, and is heated and vaporized by the industrial steam. The generated secondary steam with water droplets enters the steam-water separator from the lower end of the evaporation chamber, the separated pure steam enters the next effect as heating steam, and the unevaporated raw water enters the next effect, and the above process is repeated. The pure steam generated by the final effect enters the condenser and is cooled by condensing water from each effect except the first effect. After removing the non-condensable gas (depending on the model, the evaporator may also be equipped with such a continuous discharge device of non-condensable gas). Condensed gas becomes water for injection. The outlet generally undergoes online conductivity testing, qualified distilled water is output as water for injection, and unqualified distilled water will be discharged.

1. Structure: The external preheater, condenser and first-effect evaporator are all designed with double tube sheets, and the inner tube sheet is expanded and welded externally to avoid cross contamination.

|

Capacity

(L/h) |

Industrial steam consumption(L/h)

|

Feed water consumption(L/h)

|

Cooling water consumption

(L/h) |

Dimensions

(mm) |

|

|

LDS100-4

|

≥100

|

30

|

110

|

80

|

1065*540*1900

|

|

LDS300-5

|

≥300

|

80

|

330

|

170

|

1610*650*2300

|

|

LDS500-4

|

≥500

|

150

|

550

|

550

|

1540*770*3150

|

|

LDS500-5

|

≥500

|

115

|

550

|

190

|

1900*770*3150

|

|

LDS1000-5

|

≥1000

|

250

|

1100

|

350

|

2200*1000*3400

|

|

LDS1000-6

|

≥1000

|

210

|

1100

|

0

|

2830*1000*3400

|

|

LDS2000-5

|

≥2000

|

520

|

2200

|

750

|

3000*1200*3600

|

|

LDS2000-6

|

≥2000

|

440

|

2200

|

0

|

3510*1200*3600

|

|

LDS3000-6

|

≥3000

|

670

|

3300

|

0

|

3600*1200*3750

|

|

LDS4000-6

|

≥4000

|

900

|

4400

|

0

|

4080*1250*4000

|

|

LDS5000-6

|

≥5000

|

1130

|

5500

|

0

|

4470*1450*4250

|

|

LDS6000-6

|

≥6000

|

1350

|

6600

|

0

|

4470*1450*4

|