Product Description

Discover the Eagle Pharma Machinery Pure Water Generation and Storage System, a leading-edge solution designed to fulfill the exacting water purity demands of the pharmaceutical, biotech, and healthcare industries. This system is meticulously engineered to produce and store water that adheres to international purity standards, ensuring optimal performance and safety in your operations. With a focus on innovation, reliability, and ease of use, this system is a vital asset for any facility requiring top-tier water quality.

Key Features:

- State-of-the-art filtration and purification techniques for consistent and reliable water quality.

- Advanced automation for smooth operation and continuous monitoring.

- Compliance with GMP standards for pharmaceutical water systems.

- Scalable and modular design for easy installation and future expansion.

- Built to last with minimal maintenance needs due to robust construction.

- User-friendly controls for straightforward system operation and management.

- Full support with documentation and validation to meet regulatory requirements.

Applications:

- Pharmaceutical manufacturing and processing.

- Laboratory research and quality control testing.

- Sterilization and cleaning of medical devices and equipment.

- Biotechnological research and development projects.

- Aseptic filling and packaging in the pharmaceutical sector.

- Operation and maintenance of industrial cooling towers and HVAC systems.

- Any application requiring high-purity water for optimal results.

Eagle Pharma Machinery's Pure Water Generation and Storage System is not merely a product but a testament to our commitment to water purity and operational efficiency. Trust Eagle Pharma Machinery to provide the highest quality water for your critical operations.

Key attributes

Other attributes

Applicable Industries

Manufacturing Plant, Food & Beverage Factory, Restaurant, Food Shop, Food & Beverage Shops

Video outgoing-inspection

Provided

Machinery Test Report

Provided

Marketing Type

Ordinary Product

Warranty of core components

1 Year

Core Components

Pressure vessel, Pump, Gear, Engine, Motor

Place of Origin

Shandong, China

Productivity

1000L/Hour-50000L/Hour

Composition

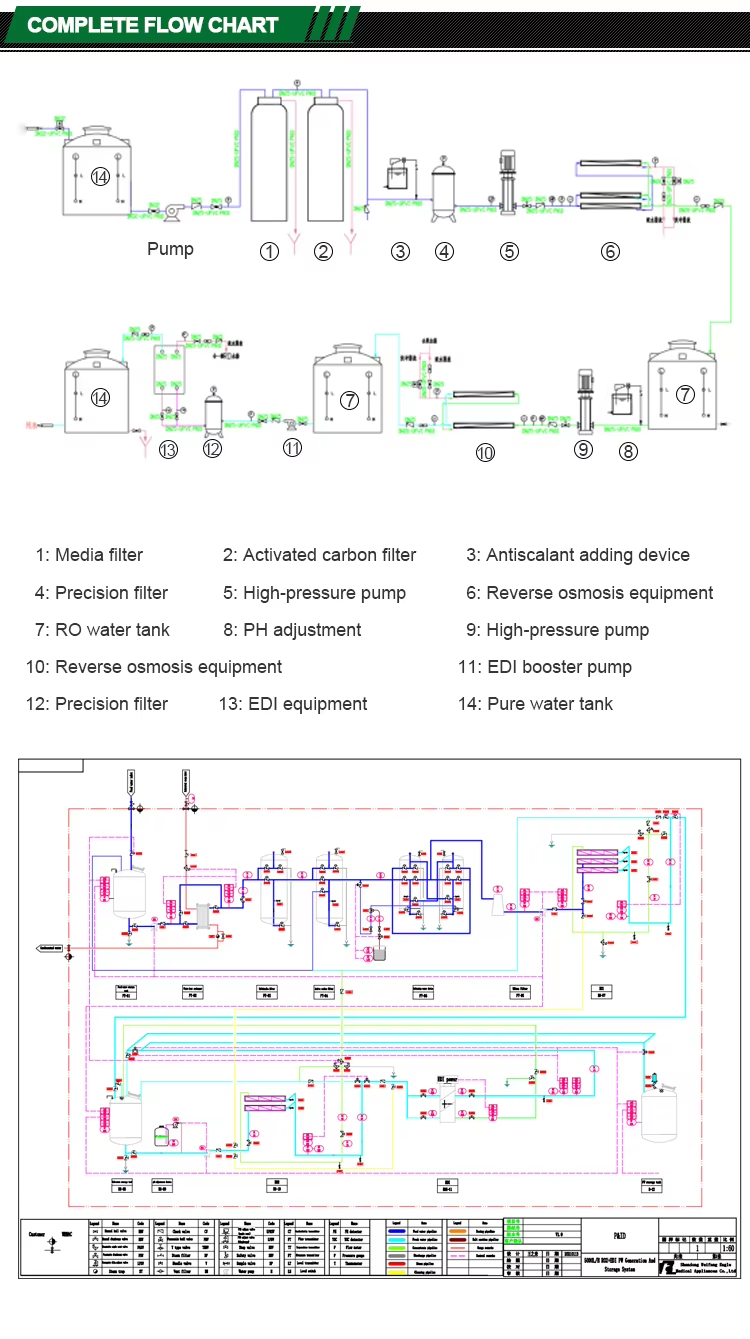

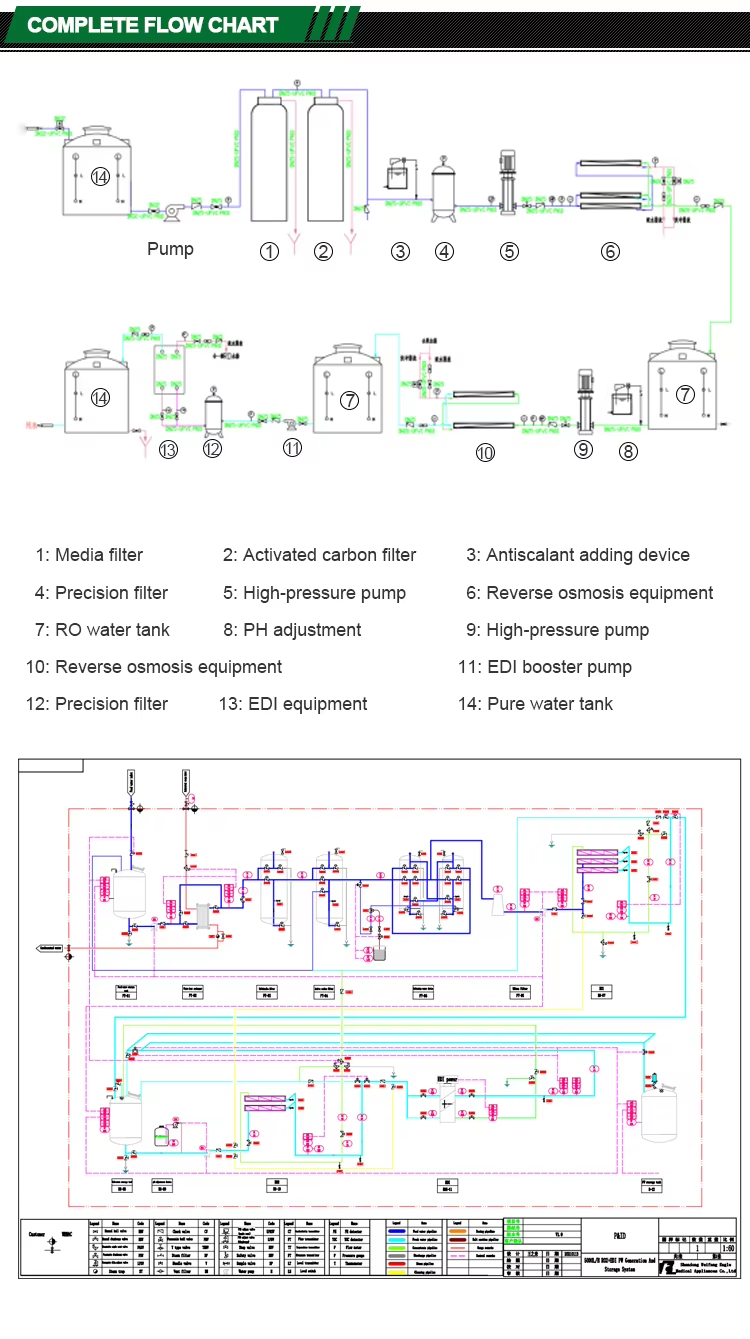

Ultrafiltration equipment,Softened water equipment,RO,EDI

After Warranty Service

Spare parts

Local Service Location

None

Packaging and delivery

Packaging Details

1. With export standard bubble film packaging, then for wooden case packaging for alone beer tanks and less brewery equipment.-LCL shipping.

2. If more tanks or complete set of brewery, with bubble film packaging, the for containers for FCL shipping.

3. By bulk carrier or independent containers, the size and quantity rely on the configurations and capacity.

4. Buyers requirement on packaging and shipping, tell us in advance.

5. Transportation method: By sea/Railway/Road/Air.

Supply Ability

Supply Ability

20 Set/Sets per Month

Ultrafiltration is a membrane separation process based on the principle of sieving separation and pressure as the driving force. The filtration accuracy is within the range of 0.005-0.01μm, which can effectively remove particles, colloids, bacteria, heat sources and macromolecular organic substances in water.

When the raw water containing hardness ions passes through the sodium resin in the exchange tank, the Ca2+ and Mg2+ in the water are exchanged and adsorbed by the Na+ in the resin, and the Ca2+ and Mg2+ are removed to remove the carbonate or non-carbonate hardness, which is softened water.

Mainly use the permeation principle of the semi-permeable membrane, and apply a pressure to it in a certain way. The force against the natural permeation direction makes the water in the concentrated solution penetrate into the dilute solution and effectively remove the dissolved salts and colloids in the water. , Microorganisms, organic matter, etc.

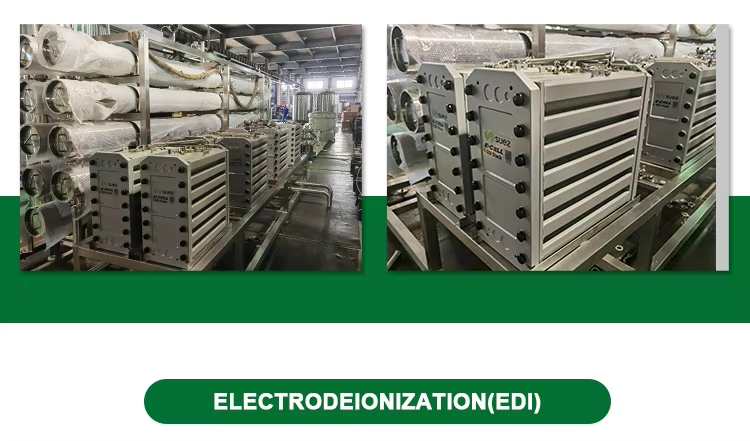

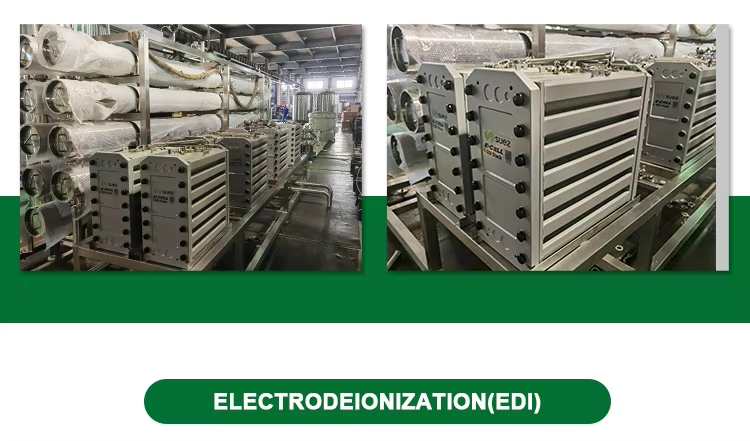

The selective permeation effect of anion and cation exchange membrane on anion and cation and the exchange effect of ion exchange resin on ions realize the directional migration of ions under the action of a direct current electric field, thereby completing the deep desalination of water.

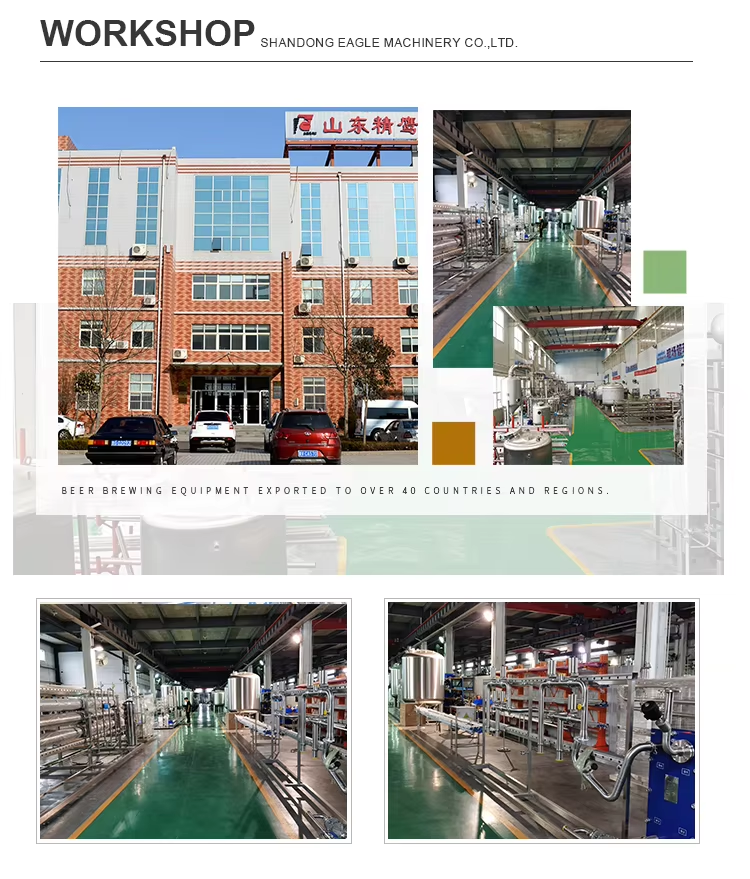

1. who are we?

We are based in Shandong, China, start from 2012,sell to Domestic Market(43.00%),North America(11.00%),South

America(9.00%),Western Europe(8.00%),Eastern Asia(5.00%),Southeast Asia(5.00%),Oceania(4.00%),Northern

Europe(3.00%),Africa(3.00%),Mid East(3.00%),South Asia(2.00%),Southern Europe(2.00%),Eastern Europe(2.00%). There are total about

201-300 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Purified water system/ Purified Water Generation Plant/ Multi Effect Water Distiller/ Multi Column Distillation Plant/ Pure Steam

Generator/ Looping System/ Liquid Solution Preparation System/ Purified water storage tank/ Shell and tube heat exchanger/ WFI

storage tank/CIP system/ Commercial Beer Brewing Equipment/ Fermentation System/ Home Brewing Equipment/ Microbrewery Equipment/

Nano Brewery Equipment/ Beer Filling Capping System/ Brewing Material Processing Machine/ Beer brewing Accessories,Ice Water Tank/

4. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,FCA;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken:English,Chinese,Korean